Back to Learning Resources

Inspection and Test Plans

An Inspection and Test Plan lays out a schedule of inspections at critical control points or 'hold points' within a process, in order to verify that things are progressing as they should be. We look at an example ITP.

Tags:

An "Inspection and Test Plan" (ITP) might also be called a "Quality Inspection Plan".

Inspection and Test Plans set out critical control points or 'hold points' at various stages within a process. Each control point is a scheduled inspection or verification activity where you will make sure that things are progressing as they should be, and get things back on track if they're not.

Inspection and Test Plans are used to control quality and are one way to satisfy the requirements of the ISO 9001 standard related to control of production and service provision.

In ISO 9001:2015:

8.5.1 Control of production and service provision

"... c) the implementation of monitoring and measurement activities at appropriate stages to verify that criteria for control of processes or outputs, and acceptable criteria for products and services, have been met; ..."

8.6 Release of products and services

"The organization shall implement planned arrangements, at appropriate stages, to verify that the product and service requirements have been met. ... "

Did you notice "at appropriate stages"? This means that inspections happen throughout the process and not just on the final output. That's a good strategy as the earlier you pick up mistakes or problems, the less it costs you.

What the standard is saying is that you must plan when, and what, and how you will check that your product or service is meeting requirements. This is what an ITP is. There is also a requirement to keep evidence of the check, which means a record of some kind.

It's up to you to determine where the appropriate points are in your process. It's also up to you to determine what your records will be.

Planned and executed properly, an ITP will ensure a consistent output.

How to prepare an ITP

In general the ITP should follow the sequence of operations, setting out what inspections are required, and clearly identify who is responsible for signing off each check.

Think through the steps and decide when in the process you want to conduct an inspection or check. Common hold points are prior to a phase of high cost/ high value work, where any pre-exisiting problems will create difficulties at the next stage, or will mean a high cost of re-work when discovered later in the process.

For each check point you need to specify exactly what to look for (perhaps refer to another document for details), how the check is recorded, and who must perform/signoff the inspection.

Once you've finalised the plan, it's a controlled document.

Inspection and Test Plan vs. Checklist

An Inspection and Test Plan is not the same as an Inspection Checklist.

An ITP tells you when in the process to perform an inspection. The details of the inspection are contained in the checklist, and are typically recorded there.

An ITP might refer to different checklists for each inspection point, or could refer to a code or standard that sets out the requirements for what and how the check must be performed, e.g. AS1012 - Methods of Testing Concrete. A simple ITP can closely match the checklist.

The Inspection and Test Plan is like a Work Instruction - what to do, and the Checklist is a form that will be filled in with data to become a record. Both the ITP and Checklist are documents that must be controlled.

An Example ITP

A common critical hold point in manufacturing is 'Incoming Goods". Before you start working with the raw materials, you want to be sure that the supplier has delivered what you asked for. If the wrong material has arrived it's better to send it back immediately, rather than after you've spent time and money working on it and perhaps can no longer return it to the supplier. A minimal inspection in this case could be to examine the supplied material certificates, check the dimensions of the cut pieces supplied, or check the part numbers in the box match the parts ordered.

In construction, the next inspection hold point usually comes after significant work as been done and prior to covering it all up in the next stage or work. e.g. prior to internal lining of the walls; prior to tiling going over the waterproofing.

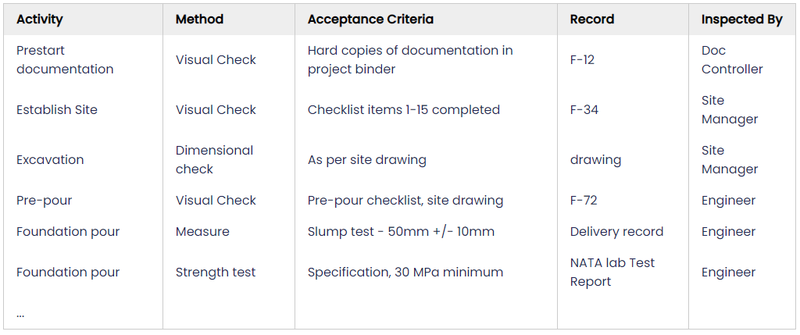

Here's an example ITP:

The detailed inspection instructions for each step in this example are contained within separate checklists. e.g. F-12 is a simple list of all the documentation that must be present before the site preparation can commence. The Pre-pour checklist, F-72, includes a space to record any rectification required. Both items are important records for the project and can help to resolve any later disputes.

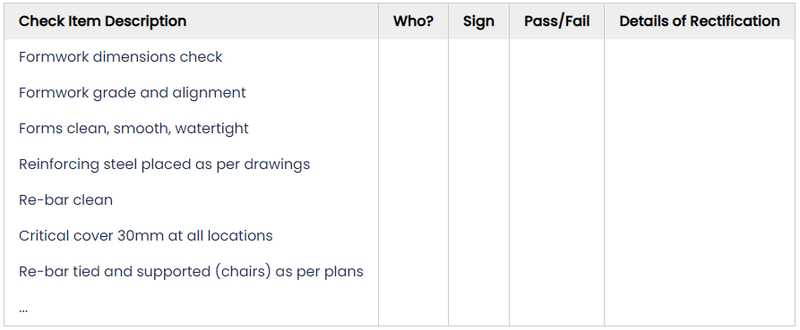

e.g. Pre-pour Checklist:

Each checklist will also include a header to collect project information, date, final signoff, and other identifying information.

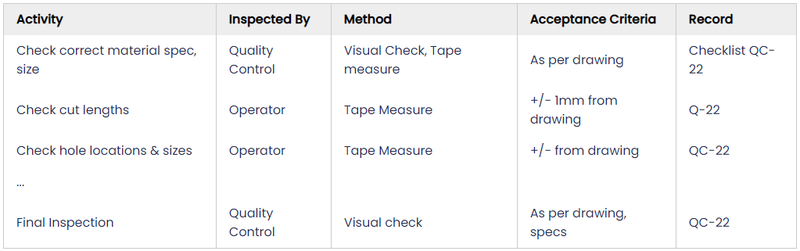

Another ITP for a welded frame:

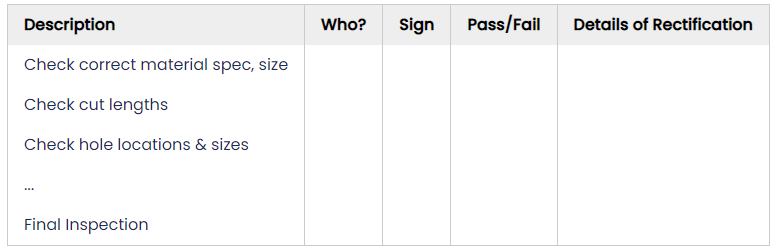

And a closely matching Checklist:

What's the difference in the "who" in the plan versus the "who" in the checklist? The plan says which role is responsible for performing the inspection, and the checklist records the actual person who performed the inspection on the day.

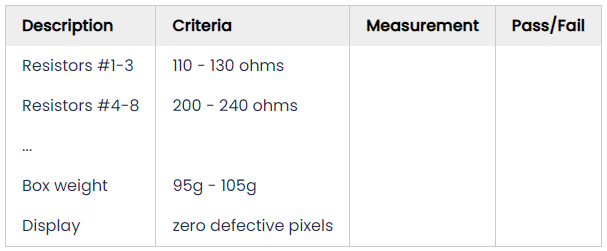

For technical production work, the checklist can include values to be measured and the range of accepted values - e.g., an inspection checklist for a circuit board assembly:

In this case, one person completes the entire checklist so the "who" information and rectification details are contained in the header and footer sections of the checklist.

ITPs in Quality Systems Toolbox software

ITPs are important for controlling quality and belong in your quality management system. There's a few ways to handle them in Quality Systems Toolbox software.

The quickest option is to upload your existing ITPs and associated checklists as controlled documents. This means that changes are controlled, new versions need approval before release, and old versions are retained for reference (but hidden).

If you prefer to collect data digitally, you can build your ITP checklists as a 'Form' in Toolbox and save the records in a 'Register' for secure storage and easy retrieval.

Other resources

qualityinspection.org has a great infographic on Preparing a Quality Inspection Checklist

with some more Examples of inspection checkpoints here.